Gonzalo Montoya,Superintendente Innovación y Tecnología

Currently there is a system for loading grinding media (GM) to SAG mills, which is based on a gate that should pass and count one by one GM, also known as a steel ball. However, in certain circumstances, whether due to excess dust in the environment, failure of the light or the sensor of the bodies, CM avalanches occur leading to overloads in the associated mill.

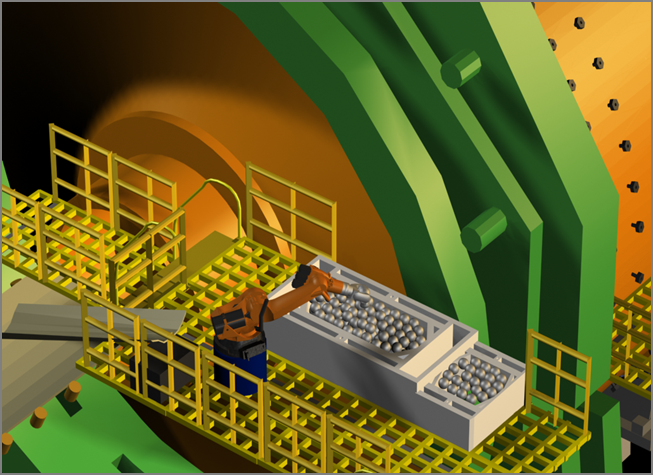

The project consists of carrying out the loading or GM task by means of a robot, which lifts one or more grinding media (depending on the load rate set point) and takes them to the loading chamber of the mill. Each type of GM has a certain mass, therefore the robot will be able to know the weight it is lifting and deliver the precise amount of GM depending on the type of ore that the operator specifies to the loading system.

1. Reduce SAG mill shutdowns to know its internal load level and know precisely how many GM's there are inside.

2. Greater stability in mill operation due to continuous load v/s feed blocks and elimination of three overload incidents per year.

3. Estimated improvement of the treatment of a Mill 15 ton/hour (approx 140 kUSD/year).